- Ediabas Tool32 Download

- Ediabas Tool Set 32 Download

- Ediabas Tool32 Free Download

- Ediabas Tool32 Software Download

- EDIABAS Toolset 32. Microsoft ASP.NET MVC. Adobe Acrobat Reader DC.

- This thread describes how I install and configure BMW Standard Tools, the suite of BMW software that includes INPA, NCS Expert, WinKFP, Tool32. I have my own custom way of doing this that is the shortest and simplest steps I could figure out. Windows 7 or 10 (32-bit or 64-bit).

Which .prg file should you choose for Fxx Jobs in Tool32? This is a short guide of how & which .PRG file to load into Ediabas Tool32 based on your current car.

Disclaimer: The write-up was made by a Swiss BMW expert. Try at your risk.

Tool needed:

BMW Standard Tools is a group of software distributed by BMW Group that contains several interoperating applications and drivers, including NCS Expert, WinKFP, NFS, Tool32 etc. Following are the.

BMW INPA K+DCAN USB cable

INPA & the EDIABAS package which includes Tool32. Search the obdii365 official blog to get some free download resources.

Process:

1. Start BMW INPAsoftware by right-clicking INPALOAD.exe file and selecting ‘Run as administrator’. Load Inpa software.(Fig. 1).

2. Select your relevant Fxx car. I.e F10, press F3.

3. The Script selection window will appear. Select the 1st option on the right – FUNCTIONAL JOBS (Fig. 2).

4. The Select series (Baureihenauswahl) window will appear. Select F1 (Fig. 3).

5. The Job main menu will appear. Select F2 – Identifikation (Fig. 4).

6. Here you can see the result of my car (Fig. 5). Note I have highlighted in yellow the SGBD column. This is the SGBD name and the .PRG file name that you will need to open in Tool32 for working on your modules.

7. Start Tool32 by right-clicking tool32.exe file and selecting ‘Run as administrator’. Tool32 should load.

8. Select File->Load SGBD, Group file.

9. Browse to the EDIABASECU folder, and search for the file name based on the listed yellow column entry. In this example, I’m loading the AIRBAG module file, named ACSM3.PRG (Fig. 6).

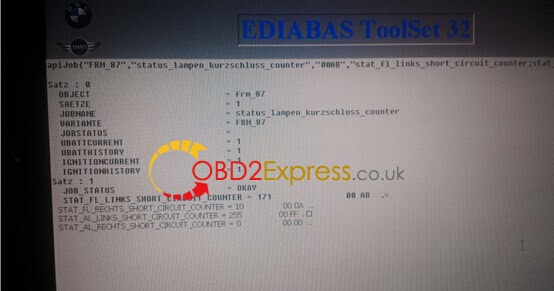

10. Once loaded, You will see on the left a list of Jobs available for your module. I have launched the fs_lesen job which is to read the fault memory either double-clicking on it or by selecting it & pressing F5. The Job Results will appear in the window below (Fig. 7).

Please be careful with running Jobs in Ediabas Tool32.

Some Jobs will literally wipe your ECU to a point that only the dealer or even worse – BMW Munich can recover, and to state that it wasn’t your fault will be difficult..

Some wording might not have the context you would expect so research jobs with words like: Initialisierung, Reset, Sperren, Default or Loeschen before you launch them.

In the context of Fault Memory, the Job to clear it is ‘fs_loeschen’.

Hope this helps. Would be great if someone can follow-up with similar instructions for Exx series.

BMWTool32 Tutorial of Coding Oil Temperature for E series

TOPICS:BMW ICOM A2 CodingBMW K+DCAN Cable

POSTED BY: BMW ICOM JANUARY 18, 2017

It’s a part of ediabas toolset 32 manual of oil temperature coding for bmw E series. Bmwicomshop.com holds no responsibility for any illegal or improper usage. Carry out this procedure at your own risk.

You need prepare:

A working BMW ICOM A2 or ODB 2 cable (K+DCAN cable) is ready for use and connected to the car.

A working PC better running with Windows XP

ediabas toolset 32 download

Prerequisites Tool32 operate and deal with hexadecimal numbers.

Oil temperature coding… Here you go…

Start Ediabas ToolSet 32 and load Komb60.prg. File -> SGBD, Load Group File

ediabs-tool32-oil-temperature-coding (1)

Job codierdaten_lesen, there simply enter as argument 0x3105. And job once

Execute.

ediabs-tool32-oil-temperature-coding (2)

The encoding data should then appear in Results

Ediabas Tool32 Download

ediabs-tool32-oil-temperature-coding (3)

The result is the same as you get with c_c_Lesen.

For job c_c_lesen you have to specify the following buffer as an argument and DATA

Hook

C_c_lesen Buffer:

01 01 01 00 00 00 00 00 00 00 00 00 00 00 00 00 05 00 00

FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF

FF FF FF 03

ediabs-tool32-oil-temperature-coding (4)

As a result you get:

ediabs-tool32-oil-temperature-coding (10)

The red bytes are the encoding data. As you can see the FF placeholders in the

Transferred buffer.

01 01 01 00 00 00 00 00 00 00 00 00 00 00 00 00 05 00 00

FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF

FF FF FF 03

01 01 01 00 00 00 00 00 00 00 00 00 00 00 00 00 05 00 00

73 12 0D 00 00 36 00 67 00 98 00 CA 00 00 00 BC 01 78 03 35 05

F1 06 6E 03

To code oil temp you have to change the blue:

73 12 0D 00 00 36 00 67 00 98 00 CA 00 00 00 BC 01 78 03 35 05

F1 06 6E

The valuesfor the scale division are 36 67 98 CA. The value 6E is for

KVA.

We have to change the scale division for the oil temperature display. Therefore

We need a correction value (46-48) to the desired temperature display.

add.

To program 50-150℃, we will divide the scale as follows.

50℃, 75℃, 100℃, 125℃, 150℃

Ediabas Tool Set 32 Download

ediabs-tool32-oil-temperature-coding (9)

Temperature + correction value = decimal value = convert to hex value

The value 6F turns on the oil temperature display.

The result of the calculations is as follows

73 12 0D 60 00 79 00 92 00 AB 00 C4 00 00 00 BC 01 78 03 35 05

0D 07 6F

Ediabas Tool32 Free Download

0D and 07 are simply adopted. Currently its function is unknown

Then copy the changed values into buffers and the job c_checksumme in T32

And specify the buffer with the new values as an argument. (Data

Do not forget)

Job c_checksumme Argument:

Ediabas Tool32 Software Download

01 01 01 00 00 00 00 00 00 00 00 00 00 00 00 00 05 00 00

73 12 0D 60 00 79 00 92 00 AB 00 C4 00 00 00 BC 01 78 03 35 05

0D 07 6F 03

As a result you get a new checksum, in my case 68

01 01 01 00 00 00 00 00 00 00 00 00 00 00 00 00 05 00 00

68 12 0D 60 00 79 00 92 00 AB 00 C4 00 00 00 BC 01 78 03 35 05

0D 07 6F 03

Then copy the entire buffer as an argument and by job

C_c_scribe, encode DATA do not forget.

Then execute job_controller_reset.

ediabs-tool32-oil-temperature-coding (6) ediabs-tool32-oil-temperature-coding (5)

If necessary, run the date and time using the job time_time_time.

This takes the time from the laptop.

Now it is possible to test the temperature using the job_oeltemperature

Oil temperature display works

ediabs-tool32-oil-temperature-coding (7)

Give the desired oil temp in℃ as an argument. E.g. 100 and job once

To run.

If the display is not exactly correct, 100℃ should be at 10L, the

Correction value. In my case I am better with correction value 48

hazards. The hex values are then to be adjusted and the checksum must be renewed

be determined. Then write the new buffer with c_c_ and write

Control_reset_reset.

If everything is correct. Job control_oeltemperatur_aus.

(BIG THANKS to deliciouscars in the CT community)